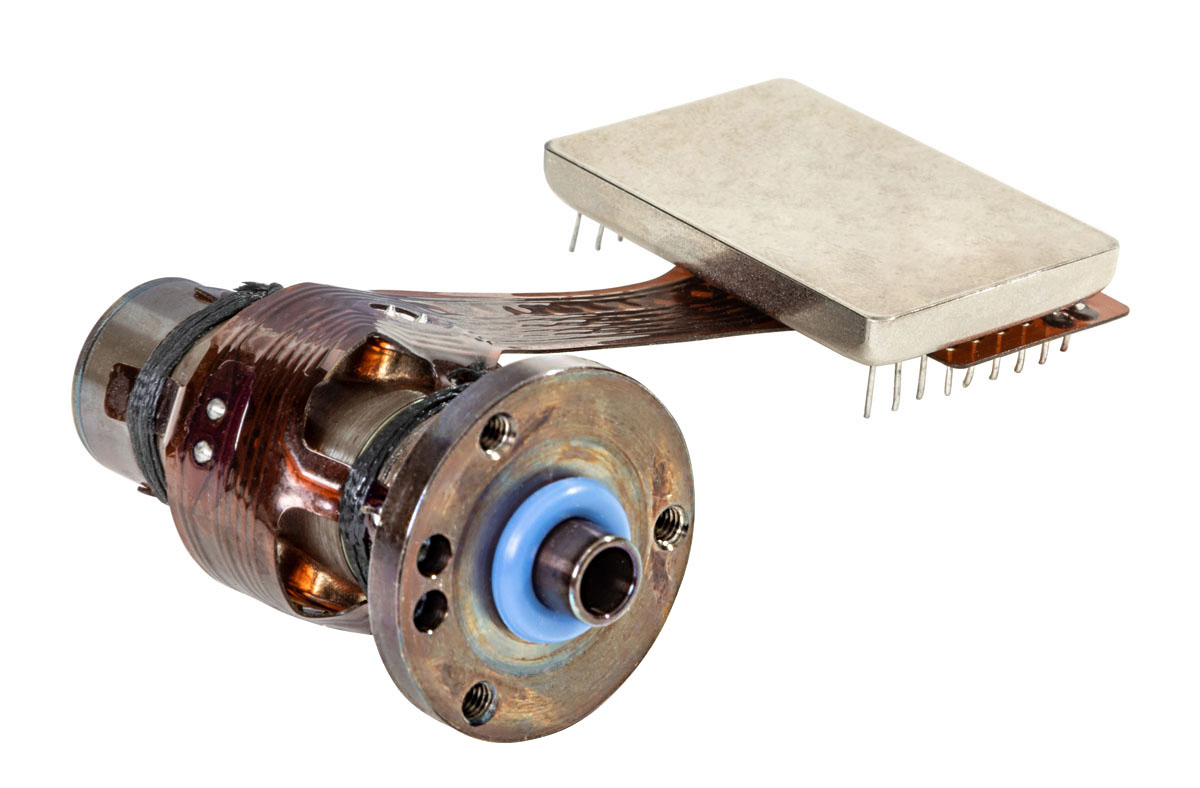

Vibrating Cylinder Pressure Sensors

Auxitrol Weston boasts over fifty years of Pressure Sensor specific expertise, including the development of our unique Vibrating Cylinder technology which, with no reported history of drift issues, is arguably the world’s most accurate and stable pressure sensor. Vibrating cyclinder technology has proven to be extremely dexterous having made an initial impact with the Aerospace industry, it has now been subsequently adopted across the widest range of industrial and commercial applications where accuracy is paramount. Aerospace sensors have achieved in excess of 2.25 million hours MTBF.

The vibrating cylinder sensors are designed and manufactured internally within our own dedicated clean environment. The technology offers an unrivalled accuracy (<0.005% FS) whilst maintaining class leading stability year on year (<0.002% FS) over the operating temperature range.

The sensors are primarily used in aerospace within Air Data Test Sets as the benchmark for pressure calibration, are part of the Air Data System measuring altitude and airspeed as well as pressure measurement in the Electronic Engine Control System. They cover a range of pressures from 130kPa to 5MPa whilst exceeding the RVSM and CAA/FAA requirements to maintain flight safety. Other industry applications include semiconductor wafer positioning interferometer pressure correction and meteorological barometric pressure measurement.

Features

- < 0.005% FS typical accuracy over temperature range -55°C to +125°C

- < 0.002% FS typical stability/year maximum over a temperature range of -55°C to + 125°C

- > 2.25 Million hours MTBF in Trent 500 / 700 / 800, RB211-524, BR710 FADEC, A330 & B777

- 130kPa to 5MPa pressure capability

Benefits

- Best in world for accuracy and drift

- Exceeds RVSM and CAA/FAA requirements to maintain flight safety

- Low cost of ownership